smartbuildingmag.com

11

'21

Written on Modified on

Johnson Controls News

How digital twin simulation and modeling are making HVAC systems and buildings smarter and safer

By Jason Pelski, Platform Product Management, Digital Solutions, Johnson Controls.

Facility managers face an ongoing challenge to reduce building expenditures while increasing efficiency of existing building data. With HVAC being the most expensive outlay – typically comprising half of maintenance, repairs and operations (MRO) – the desire to lower operational costs while striving to decrease monthly heatingand cooling chargesis a constant struggle. The HVAC system also plays an increasing role in creating healthier buildings for building occupants, particularly in the wake of COVID related infectious diseases. Creating a healthy working environment is a key focus for customers.

New developments in the Internet of Things (IoT) have made buildings smarter, allowing HVAC systems to be more efficient while enhancing the health and safety of occupants. IoT technology also improves other building systems such as fire, security and lighting. However, these solutions are often siloed and do not take into account how these disparate activities in a facility interact with each other.

Imagine having the power to digitally connect and integrate all building systems into one unified application to ensure all HVAC equipment is completely optimized with other building systems. A new advancement in IoT technology – digital twin – allows facility managers to harness and democratize the power of data and simulation to decrease operational costs, increase energy savings and enhance occupant health.

A digital twin is a connected, digital replica of a physical product, asset or system.

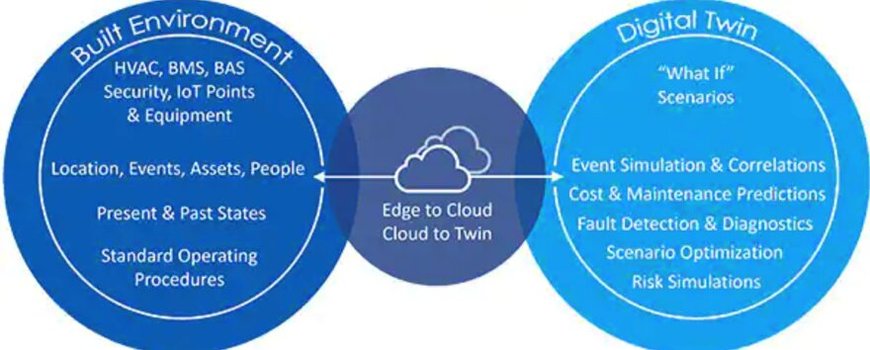

Digital Twins in the Built EnvironmentA digital twin is a connected, digital replica of a physical product, asset or system. Digital twins are used to represent the past and present state of products or systems and then simulate, test and predict future processes by answering “what if” questions. In the past, digital twins functioned as separate entities, focusing on one building system such as HVAC, security or lighting.

Today, a digital twin can be deployed at the enterprise level, providing a complete digital representation of the physical environment and holistic view of a building’s entire operations in the cloud. Digital twins bring together data across the built environment to unlock greater insights for applications and machine learning modeling.

Data Collection for Systems Integration

For a digital twin to be truly successful, data must be enriched from a variety of sources such as embedded sensors (including those in an HVAC unit), wireless sensor networks, building information modeling (BIM) data and outside weather data. Using a 3D schematics model, the digital twin can connect a multitude of performance data throughout the building – including location, events, assets and people – and then integrate with pre-defined building scenarios to create context-rich data sets across the “living” building. The data management platform provides automated context-aware data enrichment, which confirms data integrity and accuracy for machine learning models.

Digital Twin for HVAC Systems

HVAC has a significant impact on MRO. New digital twins collect data from a variety HVAC equipment – including chillers, air handling units (AHUs), variable air volume (VAV) boxes, heat pumps and more – and then develop simulations in the cloud to enhance preventive maintenance and help with both short-term and long-term building challenges.

For example, digital twins can support back-to-work solutions during the COVID-19 pandemic by creating a building pathogen profile to enhance air circulation while minimizing energy consumption. As a long-term solution, a digital twin can overlay and track occupant locations to see how they impact Indoor Air Quality (IAQ) and energy consumption. Older HVAC systems can use “bridge” edge platforms – a low-cost gateway – to connect brownfield environment devices and retrofit older equipment (based on what data the older systems can provide).

Driving ROI in the HVAC Lifecycle

According to the National Institute of Standards and Technology, the global building industry loses an estimated $15 billion annually due to the lack of common data models for applications and systems within a building.

Digital twins can help create smarter buildings by automating processes through machine learning. A building twin allows operators to select optimal HVAC systems via simulation, what-if analysis and standard operating procedures (SoP) for each selected system by simulating asset/equipment relationship. This becomes increasingly important when equipment is replaced and commissioned. The performance of system changes can be measured and tracked per existing SoP for performance improvement through machine learning.

After tracking day-to-day HVAC operations and “learning” about routine maintenance calls, buildings can actually make decisions on their own, eliminating the need for facility managers to manually schedule service visits. In short, digital twins serve as the “brain” that helps make the building self-aware.

Digital twins also allow facility managers to conduct simulations on HVAC systems to optimize energy management. For example, a VAV box collects data that can be used to create scenarios based on occupant experience, temperature zones, etc. Facility managers can turn those simulations into real-world applications to drive energy efficiencies.

Ideal for Old and New Buildings

A digital twin can be used in both new construction and existing buildings. Unlike architectural blueprints, a digital twin can evolve throughout design, construction and commissioning. It can go through thousands of changes and millions of simulations before it eventually guides construction of the actual building. For existing buildings, a digital twin evolves as more data is measured or acquired and additional real-time sensors are integrated.

Getting Started with Digital Twin

Buildings already using an enterprise management solution can realize immediate benefits from a digital twin. Modeling and simulations can be deployed across multiple buildings such as corporate offices, hotel chains, college campuses, hospitals, banks, stadiums and healthcare facilities. HVAC data points can be collected and analyzed for each facility and adjusted accordingly.

A digital twin takes buildings on the journey to smart. It brings together all data necessary for predictive algorithms and artificial intelligence systems, from fault predictions on equipment to building utilization and optimization. With a digital twin, buildings become smart and then smarter…safe and then safer…healthy and then healthier.

Jason Pelski is Cloud Platform Product Lead for Johnson Controls, where he provides product-driven leadership for the OpenBlue digital cloud platform. He is focused on digital transformation of buildings, occupants, and operations, as well as democratizing data across the digital ecosystem using cloud-native architectures, digital twins, AI, and best in class security to create and accelerate value driven customer solutions across the entire business portfolio.

www.johnsoncontrols.com